DRS Wheel Block System

DRS 160 Wheel Block System High Performance Crane Travel Solution

The DEMAG DRS 160 wheel Block Systemis a high-performance, modular core component of crane travel mechanisms. It is renowned for its exceptional reliability, high load capacity, and flexible configura

The DEMAG DRS 160 wheel Block System is a high-performance, modular core component of crane travel mechanisms. It is renowned for its exceptional reliability, high load capacity, and flexible configuration options , and is widely used in various industrial cranes, gantry cranes, and material handling systems, especially in harsh environments that demand heavy loads, high operational intensity, and long service life.

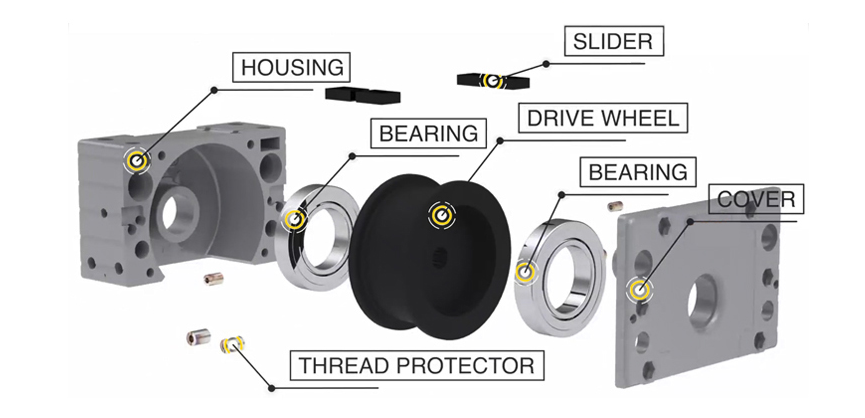

Basic Structure & Components

This wheel Block system is a highly integrated modular unit, known for its durability and efficient operation. Its main components and functions are as follows:

1. HOUSING

Function : This is the foundation and core support structure of the entire wheelset. It is typically made from high-strength cast steel or welded steel plates, and it connects to the crane's balance beam or end beam through the hinge holes.

Features : The design is robust, capable of withstanding large shock loads and bending moments. It includes precisely machined chambers for bearing installation.

2. DRIVE WHEEL

Function : The component that directly contacts the track, responsible for transferring traction force and carrying the load. It converts the torque from the drive motor into the force that moves the crane.

Features : Typically made from high-strength alloy steel, with the wheel surface subjected to surface hardening treatment for high hardness and wear resistance, significantly extending its service life. The wheel is usually equipped with double flanges to prevent derailment during operation.

3. BEARING

Function : Connects the axle and housing, supporting the entire wheel blockand allowing the wheels to rotate smoothly with low friction. It bears significant radial loads (from the crane's weight) and some axial loads (from guidance and impact).

Features : Typically uses large, heavy-duty rolling bearings (such as tapered roller bearings), designed for high load capacity and long service life, often designed for lifelong lubrication or equipped with convenient lubrication interfaces.

4. SLIDER

Function : A key protection and adjustment component. It is installed at the bottom of the housing, either in front of or behind the wheel. Its primary functions include:

Safety and Guidance : In the event of wheel damage or bearing seizure, the slider acts as a "fuse" to make contact with the track, allowing the crane to continue moving for a short distance, preventing further damage to the hub and preventing more serious accidents. It also provides some guidance.

Gap Adjustment : It serves as a shim to fine-tune the relative position between the wheel and the track, ensuring wheel block alignment.

Features : Typically made from wear-resistant materials (such as hardened steel or composite materials), and is easy to replace.

5. COVER

Function : Installed on the outside of the housing to seal the bearing chamber.

Features : The primary purpose is to prevent dust, moisture, and other contaminants from entering the bearing and to prevent grease leakage. It is typically equipped with sealing rings to ensure a good sealing effect, which is crucial for bearing longevity.

6. THREAD PROTECTOR

Function : This is a detail-oriented but important component. It is screwed onto the exposed bolts or threaded rod ends.

Features : Its main purpose is to protect the threads from damage, wear, or corrosion during transportation, installation, or use, ensuring that the bolts can be easily removed during maintenance. This reflects DEMAG's meticulous design consideration for reliability and ease of maintenance.

Key Features & Advantage

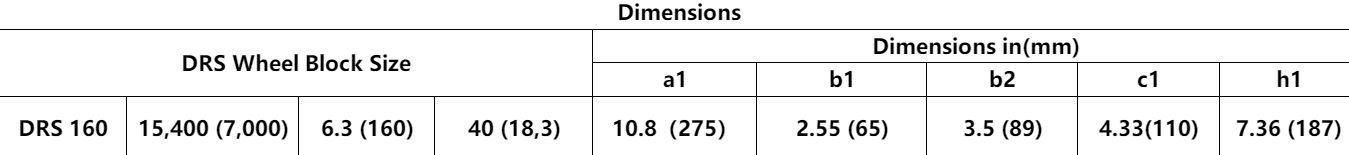

High Load Capacity : It has a maximum wheel load capacity of 7000kg, enabling it to handle extremely heavy loads.

Exceptional Reliability & Long Service Life : The use of high-quality materials, precision manufacturing, and optimized design ensures very low failure rates and long service life, reducing downtime and maintenance costs.

Automatic Load Balancing : The balance beam design is a core advantage, effectively compensating for track errors, reducing flange wear and the "rail biting" phenomenon, and protecting both the track and the wheelset.

Modular Design : The system offers various standard configurations (such as drive wheelsets, idler wheelsets, double flanges, no flanges, etc.), allowing for flexible selection and combination based on specific crane requirements (load, span, speed), simplifying design and maintenance processes.

Smooth Operation & Low Noise : Optimized mechanical design and high-quality bearings ensure smooth operation, minimal vibration, and low noise, improving the working environment.

Ease of Maintenance : The high standardization of components makes them easy to inspect and replace. The bearing housings are often designed for maintenance-free or easy lubrication.

Application Scenarios

The DEMAG 160 wheel blocksystem is not a general-purpose component, but rather a specialized solution designed to meet harsh, high-strength, and high-reliability industrial environments . Its excellent load capacity, stability, and durability play an irreplaceable role in the following key areas:

1. Industrial Overhead Cranes

Typical Scenarios : Heavy machinery manufacturing workshops, steel metallurgy industries (such as steelmaking and rolling mills), power plants (such as turbine and rotor assembly workshops), large equipment assembly lines, and scrap handling plants.

Specific Applications : The system is primarily used in the main trolleys and cross trolleys of heavy and ultra-heavy double girder overhead cranes. These cranes frequently lift extremely heavy loads (such as large castings, rollers, generator rotors, and large molds), ranging from tens to hundreds of tons.

2. Gantry Cranes

Typical Scenarios : Container terminals and yards: Conversion systems for rail-mounted gantry cranes (RMG) and rubber-tyred gantry cranes (RTG).

Shipbuilding and marine engineering: Used for hull assembly and large component transportation.

Large precast component workshops: Workshops for producing bridge components, cement slabs, steel structure components, etc.

Open storage yards: Used for handling timber, steel, and bulk goods.

Specific Applications : As the walking mechanism beneath the gantry crane's legs, it drives the entire massive structure to move precisely along the tracks.

3. Stacker Cranes

Typical Scenarios : Automated high-bay warehouses (ASRS), logistics distribution centers, cold storage warehouses, etc.

Specific Applications : Used to drive stacker cranes on elevated tracks, achieving precise positioning between shelving aisles.

Technical Specifications & Selection

Summary

The DEMAG 160 wheel system is not just a simple travel component but an integrated high-performance system that combines exceptional engineering, reliability, and intelligent design. Choosing this system means selecting a longer service life, lower overall maintenance costs, and higher operational safety for your cranes. It is one of the top solutions for material handling applications in heavy industries.

If you would like to explore the suitability of this solution for your specific application, our engineers can provide customized analysis and technical support. Contact us !