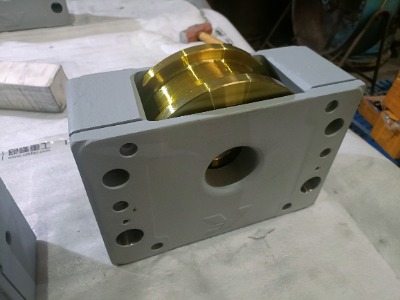

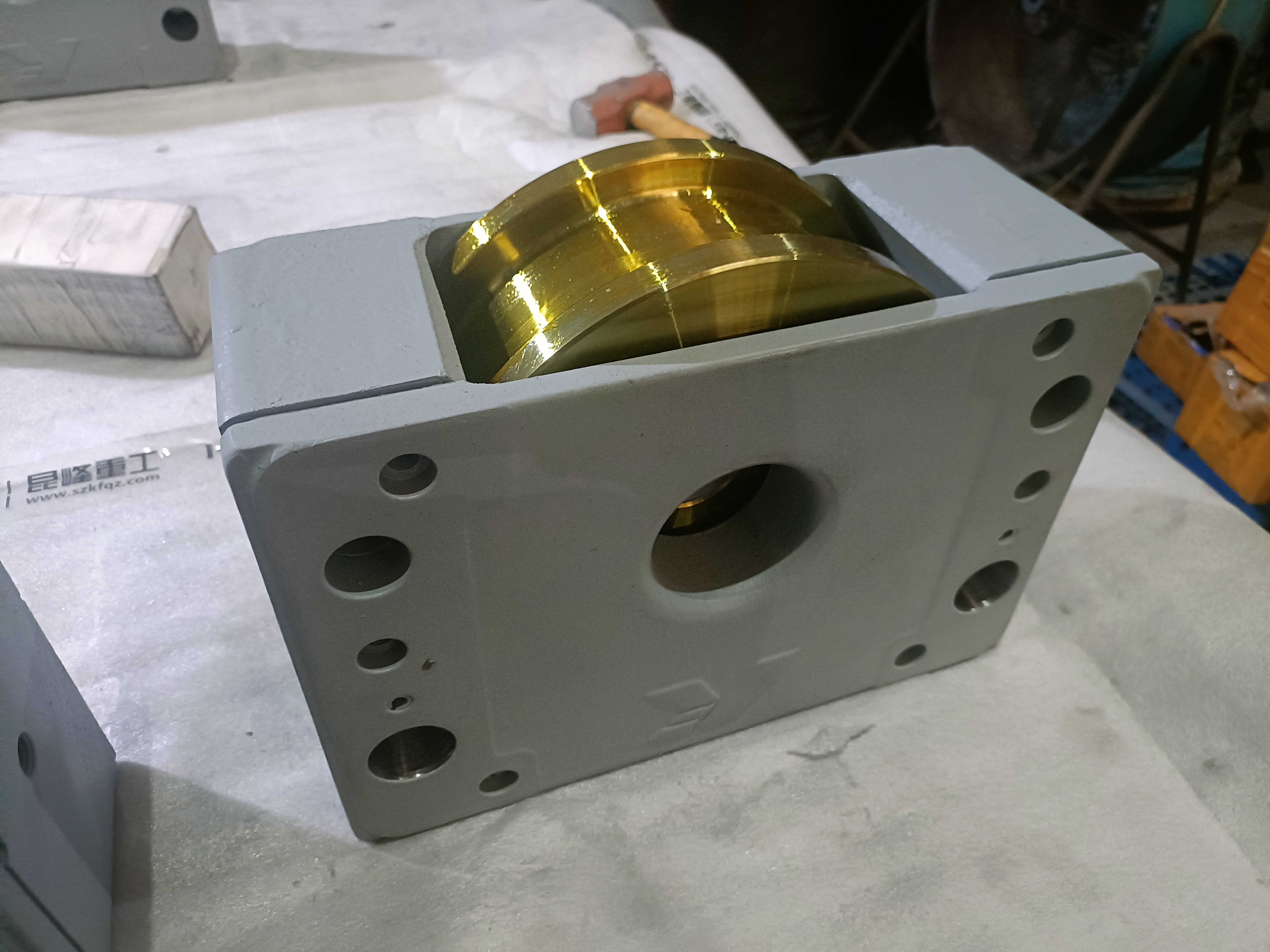

DRS Wheel Block System

DRS 125 Maintenance for Longer Crane System Life

Learn expert tips to extend the service life of Demag DRS 125 crane travel wheel blocks and maximize your ROI through proper installation, maintenance, and OEM support.

In modern industrial production, the travel system of overhead cranes bears significant loads, and its performance directly affects production efficiency and equipment reliability. As an industry-leading crane travel wheel block, DRS 125 stands out with its excellent design and reliability, making it the preferred choice for many companies. However, ensuring its long-term stable operation requires proper maintenance and management. This article will discuss how to extend the service life of the DRS 125 and enhance return on investment through proper installation, daily maintenance, lifecycle cost analysis, and spare parts and service.

1. Installation Guide: Ensuring a Solid Start

Proper installation is the first step to ensuring the efficient operation of DRS 125. The following are key elements during the installation process:

Installation Process: Ensure that all steps are followed according to Demag's official manuals and installation instructions. Every step, such as base support, secure connections, and circuit checks, must be strictly adhered to.

Importance of Calibration: The installation of DRS 125 is not just about physical fixation; precise calibration between the wheel block and the track is essential. Incorrect calibration can lead to unstable crane movement, increased wear, and a shortened service life.

Track Matching Requirements: The condition of the track is crucial to the wheel block’s operation. Ensure that the track is level and clean, and avoid debris, dust, or track damage that may affect the smooth running of the wheel block.

2. Daily Maintenance: Avoid Ignoring Details, Paying the Price

Daily maintenance is critical to prolonging the service life of the DRS 125. Here is a recommended maintenance schedule and key points to note:

Daily Inspection: Check daily for abnormal noises, overheating, or other signs of failure. Pay special attention to the lubrication condition of the wheel axle and bearings.

Weekly Inspection: Check the contact between the wheel block and the track, ensuring there is no loosening or misalignment of the track. Ensure that all connections between the wheel block and other key components are secure.

Monthly Inspection: Perform a thorough check every month, including the replacement of lubricating oil, replenishment of lubricating grease, and cleaning and re-lubricating all mechanical connection points. Check the wear on the wheel axle and flanges, making timely adjustments or replacements.

Lubrication Recommendations: Maintaining proper lubrication with the recommended oil and grease is essential for the smooth operation of the DRS 125. Choose special lubricants as recommended by Demag and ensure regular oil changes to prevent degradation.

Common Fault Troubleshooting

Abnormal Wear: Check for excessive wear, especially on the wheel flange and bearings. Uneven wear may indicate improper installation or track issues.

Noise Diagnosis: Unusual noise is often a sign of excessive friction or component wear. Regular noise inspections will help detect and address issues in time.

3. Lifecycle Cost Analysis: High Initial Investment for Low Long-Term Costs

Although the initial purchase cost of DRS 125 may be higher, its long service life, low failure rate, and minimal maintenance requirements significantly reduce the overall lifecycle cost (TCO). Some key advantages include:

Long-Term Stability: Thanks to its high durability and low wear characteristics, DRS 125 can operate efficiently for a long period, reducing the frequency of replacements.

Low Failure Rate: DRS 125 is designed with precision and strict quality control, resulting in a lower failure rate, which reduces downtime and maintenance costs.

Low Maintenance Requirements: Compared to other standard travel wheel blocks, DRS 125 requires less maintenance. Periodic maintenance and lubrication are sufficient to ensure its long-term stable operation, avoiding frequent repairs and part replacements.

In summary, while the initial investment may be higher, DRS 125's reduced maintenance costs and extended service life ultimately lead to a significantly lower total cost of ownership, making it a cost-effective investment.

4. Spare Parts and Service: OEM Guarantee for Stable Operation

To ensure the long-term stable operation of DRS 125, Demag provides comprehensive OEM spare parts and professional after-sales services. Using OEM parts not only ensures the quality and reliability of components but also prevents the risks associated with using incompatible parts.

Spare Parts Selection: Demag offers a full range of OEM parts to meet various maintenance needs. Using OEM parts ensures the highest efficiency and longevity for your equipment.

Professional Support: Demag provides a global network of technical support and service, with a professional repair team ready to respond quickly, ensuring the long-term stable operation of your equipment.

By regularly replacing parts and maintaining your equipment, you can ensure that the DRS 125 stays in optimal condition, reducing the risk of failure and improving production efficiency.

If you would like to explore the suitability of this solution for your specific application, our engineers can provide customized analysis and technical support. Contact us!