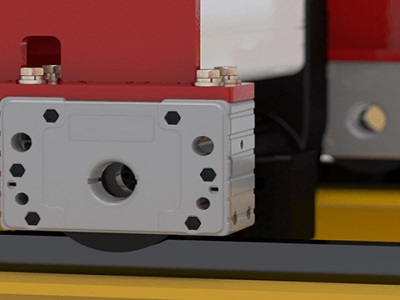

Application of DRS Drive Wheel Block in Stacker

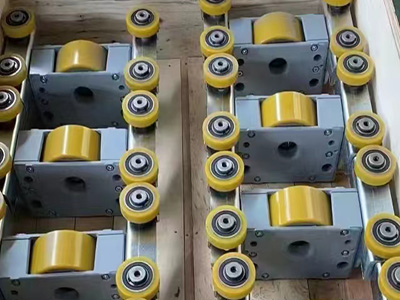

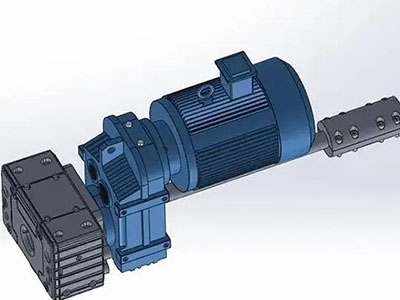

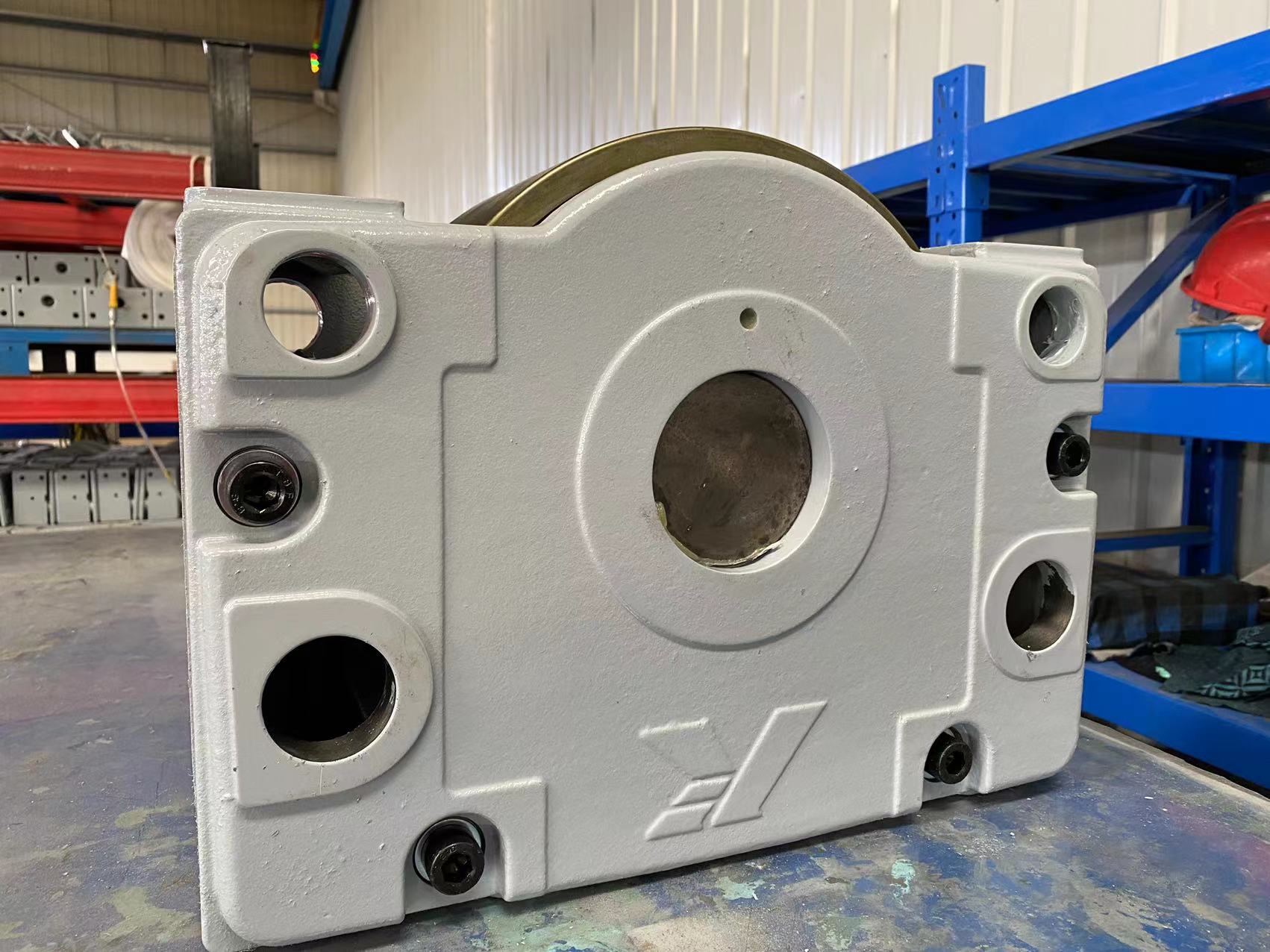

DRS drive wheel block is a modular drive wheel system, which is widely used in automation equipment and heavy handling systems. It can adapt to the complex operation requirements of stacker cranes and has good load-bearing and impact resistance.

read more