Case

The Critical Role of China Built Wheel Blocks in Indian Logistics

A certain Indian private port and multi modal logistics company is a significant port operator and logistics hub in Western India.

A certain Indian private port and multi modal logistics company is a significant port operator and logistics hub in Western India. The company operates a logistics park spanning over 50,000 square meters, handling over 5,000 containers daily. It owns hundreds of various types of container handling equipment, such as reach stackers, empty container handlers, heavy-duty equipment, and cranes.

With the rapid growth of India's import and export trade, however, the equipment at this logistics park was under unprecedented pressure.

1.High Failure Rate: India's harsh operating conditions—high temperature, high humidity, and dusty environments—caused insufficient bearing sealing in the wheel assemblies, leading to frequent ingress of dust and water, resulting in seizure, abnormal noise, and even breakage.

2.High Maintenance Costs: It was imported parts that is expensive and had long procurement lead times, causing extended equipment downtime and severely impacting park operational efficiency.

3.Insufficient Load Capacity: With the trend towards larger containers, the original wheel assemblies were deforming severely under full load operation, posing safety risks.

4.Lagging Local Service:The after-sales technical support from existing suppliers was slow to respond, unable to provide timely on-site support or maintenance training.

Our Solution:

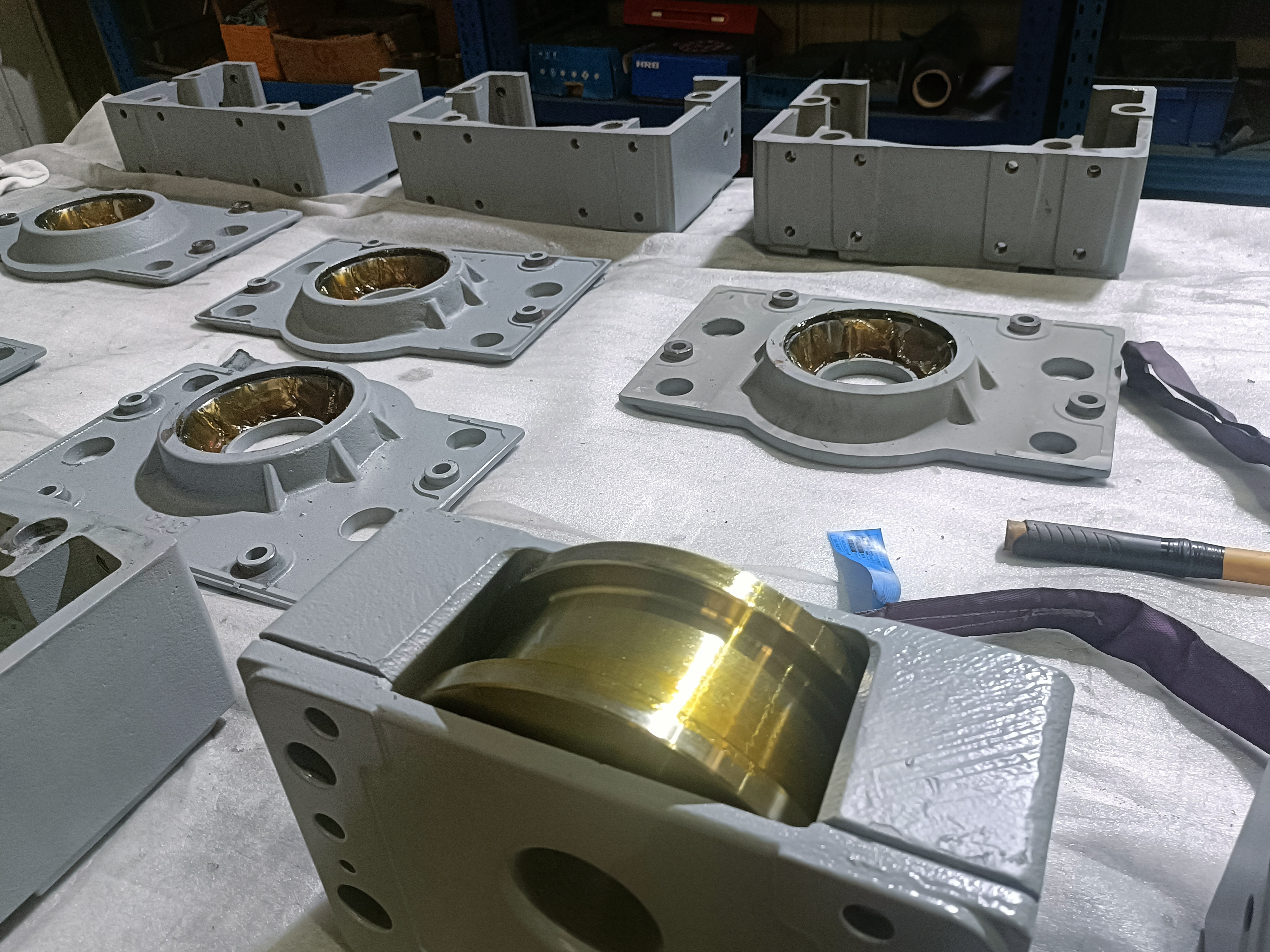

After multiple rounds of inspection and technical exchange, the Indian logistics company ultimately decided to partner with us—Shiyang, a Chinese manufacturer specializing in heavy-duty industrial wheel block system—to replace and upgrade the wheel on the first batch of 20 heavy reach stackers.

Our customized solution included:

1. Product Customization & Enhancement:

Material Upgrade: Utilized high-strength alloy steel for forged wheel cores, with quenched and tempered surface treatment, achieving a hardness of HRC 55-60, significantly improving wear resistance and impact resistance.

Sealing System Revolution: Introduced our proprietary "Triple Labyrinth Seal + Special Lip Seal" technology, filled with high-temperature, broad-temperature range grease, perfectly resisting India's harsh dust and rain environments.

Load Capacity Optimization: Designed different rated loads for each wheel position based on the equipment's actual working conditions and load spectrum, with single wheel assembly capacity up to 35 tons, ensuring safety redundancy.

2. Supply Chain & Cost Optimization:

Offered competitive pricing, saving approximately 25% on initial procurement costs compared to European brands.

Established a central spare parts warehouse in Mumbai, India, ensuring common parts are shipped within 24 hours and emergency orders are airfreighted within one week, completely solving the parts waiting issue.

1.Comprehensive Technical Service: Dispatched a team of Chinese engineers to the Indian site for installation guidance and technical briefing. Provided detailed training manuals and video materials for the Indian maintenance team, accompanied by hands-on maintenance training.

2.Implementation Results & Value Creation: Since all 20 equipment units were retrofitted with the new wheel assemblies and put into operation 18 months ago, significant results have been achieved.

3.Dramatically Improved Reliability: The failure rate of the new walking wheel assemblies decreased by 80% , with no major downtime incidents caused by wheel assembly issues.

4.Increased Operational Efficiency: Equipment availability rate increased from 82% to 96% , effectively unlocking the park's overall throughput capacity.

5.Reduced Total Cost of Ownership: Although the initial procurement cost was lower, the extremely low failure rate and rapid local service reduced the equipment's lifecycle maintenance costs by over 40% .

6.Enhanced Safety: The high-strength, high-stability wheel assemblies eliminated safety hazards caused by component failure, receiving unanimous praise from equipment operators.

Conclusion

This case successfully demonstrates that China's high-end manufacturing wins not only on cost but also competes on deep understanding of customer operating conditions, providing customized solutions, and excellent localized service as core competencies, helping international clients solve real pain points and create sustainable value. Chinese walking wheel assemblies are becoming a vital force supporting the steady advancement of global industrial giants.

If you are also looking to enhance your equipment's efficiency and reduce maintenance costs, please contact us.