Case

DRS 160 Wheel Block in Siberia

DRS 160 Wheel Block System transformed a 32-ton crane in Novosibirsk, Russia. See how we overcame -40°C extreme cold and high dust challenges to eliminate rail wear and reduce energy consumption by 15%.

Location: Novosibirsk, Siberia, Russia

Environmental Conditions: Extreme cold climate; winter outdoor temperatures drop to -40°C; significant temperature fluctuations between indoor and outdoor environments; high concentration of industrial dust.

Equipment: 32-ton Double Girder Overhead Crane.

1. Challenges Faced by the Client

The plant's original crane travel system utilized traditional open-style wheel sets. Due to the harsh Siberian operating environment, the client encountered several critical issues:

Severe Rail Wear: Poor alignment performance of traditional wheels led to frequent "rail gnawing" (flange climbing), damaging both wheels and rails.

High Maintenance Costs: The open structure allowed bearings to be easily contaminated by metal dust, necessitating a complete maintenance shutdown every six months.

Difficulty in Extreme Cold Starts: Standard grease solidified in low temperatures, causing excessive starting loads and frequent motor overheating.

2. Solution: Demag DRS 160 Wheel Block System

To address these challenges, engineers selected the Demag DRS 160 Modular Wheel Block System, specifically configured for low-temperature environments.

Core Technical Advantages

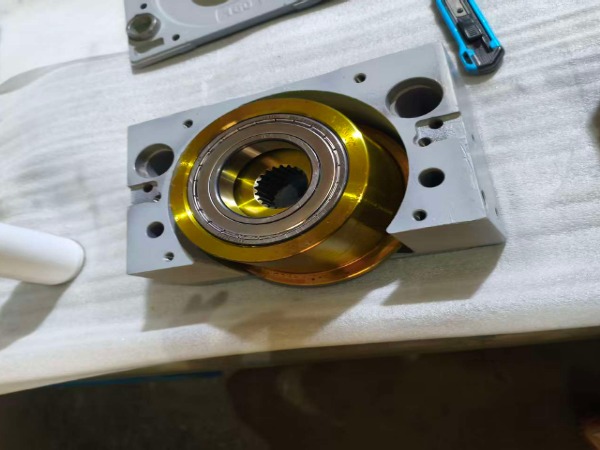

Fully Enclosed Housing: The DRS 160 features a high-grade spheroidal graphite cast iron (GGG 70) housing. With machined mounting holes on five sides, it completely encloses the bearings, blocking out the pervasive metal dust found in Siberian factories.

Precision Alignment: The system utilizes patented alignment features to ensure the verticality and parallelism of the wheel blocks over long-distance travel.

Material Adaptability: The system was equipped with low-temperature seals and specialized Arctic-grade synthetic lubricants, ensuring low starting resistance even at -40°C.

Case Specifications

Wheel Diameter: 160 mm

Load Capacity: Approx. 7.000 kg per wheel (depending on speed and material selection)

Travel Speed: 4–40 m/min (Inverter controlled)

Drive Method: Matched with Demag Offset Geared Motors for a highly compact and efficient footprint.

3. Application Results

Operational Stability: Following the upgrade, crane noise levels were reduced by 12 dB, and the rail gnawing issue was completely eliminated.

Extended Maintenance Cycles: The high-performance bearing design of the DRS 160 extended maintenance intervals to 2–3 years, removing the need for frequent regreasing.

Energy Efficiency: Optimization of rolling resistance led to a reduction in travel mechanism energy consumption by approximately 15%.

4. Conclusion

The successful application in Russia’s extreme environment proves that the DRS 160 Wheel Block System is more than just a component—it is a sophisticated kinetic solution. Through its modular design, it elevates crane "travel" performance to new heights of reliability and efficiency.

If you have similar crane upgrade requirements in Russia or other extreme cold regions, our team offers extensive experience in the DRS series selection

[ Contact us to get started on your customized engineering solution ]