Case

Wheel Block Systems in Automated Production Line

Wheel block systems are foundational to the movement and efficiency of automated production lines. Their versatility, reliability, and performance make them indispensable components in modern industrial automation.

Wheel block systems play a critical role in the smooth operation of automated production lines across various industries, including automotive manufacturing, logistics, electronics, and heavy machinery. These systems are designed to support and guide the movement of machinery and equipment with high precision, load capacity, and durability.

1. Transportation and Positioning of Equipment

Wheel block systems are commonly used to transport and position automated machinery components such as robotic arms, conveyors, tool changers, and gantry systems. With their compact design and robust load-bearing capabilities, wheel blocks enable stable and controlled motion along linear paths or curved tracks, ensuring precision in assembly and production processes.

2. Integration with Automated Guided Vehicles (AGVs) and Transfer Carts

In modern smart factories, wheel block systems are often integrated into AGVs and motorized transfer carts. Automated guided vehicles wheel blocks move materials and semi-finished products between workstations without manual handling. The high-quality bearings and precise alignment of the wheel blocks reduce friction and energy consumption, contributing to efficient, continuous operation.

3. Customizable Modular Design for Flexibility

Most wheel block systems, such as those from Demag or similar manufacturers, offer a modular design. This allows for easy adaptation to different applications, load capacities, and environmental requirements. Modules can include drive motors, encoders, brakes, and gearboxes, enabling full customization based on the production line’s specific needs.

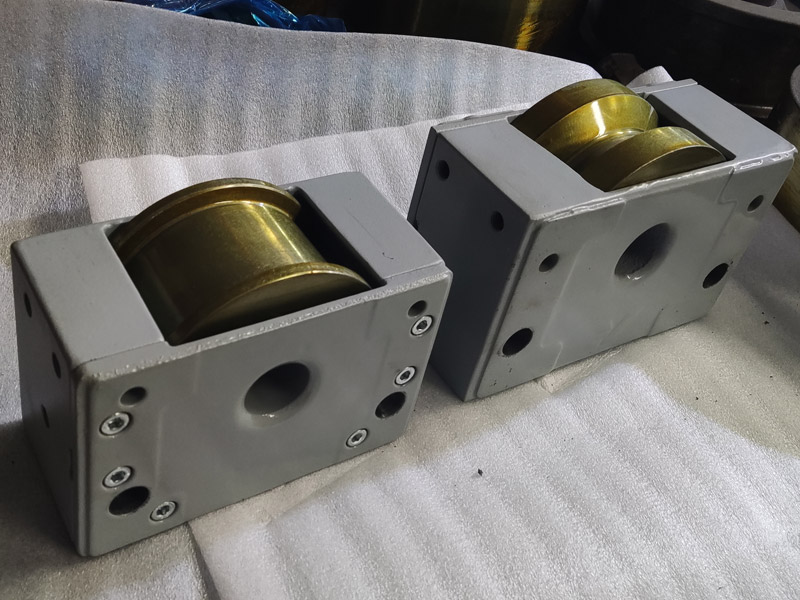

4. High Load Capacity and Durability

In heavy-duty manufacturing environments, such as steel processing or automotive body assembly, wheel blocks must carry and move extremely heavy loads. Wheel block systems are engineered with high-strength steel housings and precision-machined wheels, which can withstand heavy-duty usage, vibrations, and harsh environmental conditions, ensuring long service life and reduced downtime.

5. Seamless Integration with Control Systems

Advanced wheel block systems can be integrated into factory automation software and PLC control systems. This allows for synchronized movement and precise control of motion sequences. For instance, in robotic welding lines or painting booths, the wheel blocks enable accurate positioning of components under fixed robotic stations.

6. Improved Safety and Maintenance Efficiency

Wheel block systems are designed for easy installation, replacement, and maintenance. With features like bolted connection interfaces, grease-lubricated bearings, and enclosed housings, they help reduce the risk of mechanical failure and enhance workplace safety. Predictive maintenance systems can also monitor wear and performance, ensuring proactive servicing and minimal disruption.

In summary, wheel block systems are foundational to the movement and efficiency of automated production lines. Their versatility, reliability, and performance make them indispensable components in modern industrial automation.