Case

DRS Wheel Block System for Semiconductor Warehousing in Australia

The DRS Wheel Block System delivers ultra-low vibration (±0.5mm precision) and cleanroom-compatible performance for AS/RS in Australia's semiconductor warehousing, enhancing efficiency while meeting ISO Class 7 standards and reducing TCO.

Project Overview

In the Western Industrial Park of Sydney, New South Wales, Australia, a third-party warehousing service provider serving global semiconductor and precision electronics manufacturers has fully deployed the DEMAG DRS Wheel Block System in its newly constructed constant temperature and humidity intelligent automated storage and retrieval system (AS/RS). This warehouse is specifically designed for storing high-value, static- and vibration-sensitive electronic components. With a clear storage height of 22 meters and over 50.000 storage locations, the material handling equipment is required to meet not only extremely high positioning accuracy and operational stability but also low dust and low noise operating standards in a cleanroom environment.

Core Challenges

Micron-Level Vibration Prevention Requirements: Electronic components, particularly wafers and precision chips, are highly sensitive to micro-vibrations during handling. Vibrations generated by traditional stacker crane operations could impact product yield rates.

Environmental Cleanliness Control: The warehouse maintains an ISO Class 7 (10.000-class) cleanroom environment, requiring equipment operation to minimize particulate generation, and maintenance procedures must not introduce contamination.

Long-Term Stability in a Constant Temperature Environment: The warehouse is strictly controlled at a constant temperature of 22°C ±1°C and humidity of 45% ±5%, making the dimensional stability and long-term operational reliability of the rail system critical.

High-Frequency, Small-Batch Order Picking: Order characteristics of "wide variety, small batch size, high frequency" demand that stacker cranes possess extremely high start-stop and repeat positioning efficiency to achieve rapid order cycles.

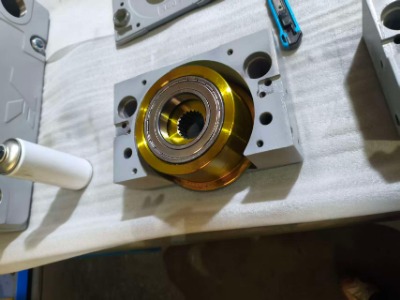

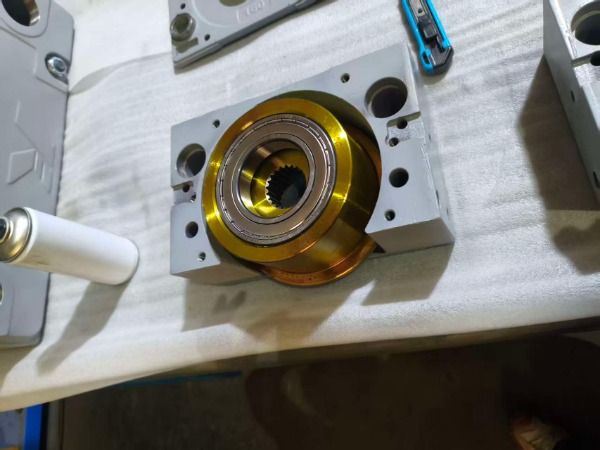

Customized DRS System Solution

Addressing the specific needs of electronic component warehousing, DEMAG provided an adapted solution:

Ultra-Quiet and Low-Vibration Design: The integrated wheel-and-rail design and optimized damping characteristics of the DRS system significantly reduce operational noise and transmitted vibrations at the source. Measured vibration amplitude is reduced by over 65% compared to traditional systems, meeting the vibration prevention standards for precision electronics storage.

Cleanroom Compatibility Optimization: All wheel blocks utilize special sealing technology to prevent lubricant leakage; key components are made from low outgassing materials; the modular design allows most maintenance to be performed in peripheral maintenance areas, maximizing protection of the core storage zone's cleanliness.

Temperature Stability Compensation: Even in a controlled environment, the system's built-in self-adapting guidance technology compensates for minor installation stresses and potential deformations from long-term operation, ensuring precision never degrades under constant temperature conditions.

Dynamic Performance Enhancement: The system's extremely low rolling friction coefficient enables stacker cranes to achieve faster acceleration, lower energy consumption, and is particularly suited for the high-frequency picking rhythm of the electronics industry.

Implementation Results

Breakthrough in Precision and Stability: Stacker crane repeat positioning accuracy remained stable within ±0.5mm, with operational smoothness significantly improved, fully meeting the storage specifications for even the most delicate components. In-storage damage rates for customer products approached zero.

Cleanliness Standards Achieved: System operation produced no visible dust, with noise levels below 65 dB. The warehouse successfully passed cleanroom certification and received the customer's "Green Clean Partner" certification.

Leap in Operational Efficiency: The average single storage/retrieval cycle time for stacker cranes was reduced by 22%. Integrated with the Warehouse Management System (WMS), daily order processing capacity increased by 30%.

Reduced Total Cost of Ownership (TCO): Benefiting from extended maintenance intervals (lubrication cycles up to 2500 hours) and exceptional reliability, the system's annual maintenance costs were 35% lower than budgeted, with unscheduled downtime virtually eliminated.

Conclusion

In the highly specialized field of intelligent warehousing for electronic components in Australia, the DEMAG DRS Wheel Block System, with its exceptional precision, superior smoothness, cleanroom environment adaptability, and outstanding reliability, has successfully defined a new standard for precision material handling.