Case

Heavy Duty DRS Travel Wheel Block Manufacturer

DRS travel wheel systems play a very important role in cranes, material transportation, transshipment, lifting and hoisting processes, saving manpower and material resources, and greatly improving operational efficiency and safety.

DRS travel wheel systems play a very important role in cranes, material transportation, transshipment, lifting and hoisting processes, saving manpower and material resources, and greatly improving operational efficiency and safety. Here are the features of MAILUN wheel blocks.

1. Wheel Material

Polyurethane: Offers excellent elasticity, wear resistance, and noise reduction. Ideal for applications requiring floor protection (e.g., epoxy floors) or quiet operation. Effectively prevents scratching of steel rails.

Stainless Steel: Provides extreme corrosion resistance, making it suitable for industries with strict hygiene requirements or corrosive environments, such as food, pharmaceutical, and chemical sectors.

Ductile Iron (GGG 70): High strength, exceptional wear resistance, and outstanding load-bearing capacity. This is the most common and cost-effective choice for heavy-duty industrial applications (e.g., steel metallurgy, heavy equipment manufacturing).

Hydropur Tire: This synthetic rubber exhibits excellent aging resistance, oil resistance, and chemical resistance. It maintains stable traction and rolling performance across various industrial environments.

Polymer: Typically refers to high-performance engineering plastics that offer specific property combinations, such as self-lubrication, high-temperature resistance, or extreme chemical inertness.

2. Customized Shell

Electrostatic Spraying: Not only enhances aesthetics but also provides a robust, uniform anti-corrosion coating. Customers can select coatings (e.g., epoxy resin, polyurethane) based on factory conditions (e.g., humidity, chemical exposure) and match corporate color standards.

Dust Cover Installation: In industries with high dust or fiber exposure (e.g., textiles, woodworking, cement), custom dust covers or sealing rings effectively prevent contaminants from entering wheel bearings and drive systems, significantly extending the service life and maintenance intervals of critical components.

3. Sealed Modular Wheel Block Housing Design

Modularity: The entire wheel assembly is delivered as a pre-assembled, pre-tested independent unit. This simplifies installation, reduces on-site errors, and facilitates quick replacement and maintenance of the entire unit.

Sealed Design: The housing employs multiple seals (e.g., labyrinth seals, oil seals) to protect internal bearings and gears, enabling reliable operation in harsh conditions (e.g., humidity, dust). This ensures lubrication purity and achieves "maintenance-free" or extended maintenance intervals.

Protection Setting Unit: This likely refers to integrated safety or condition monitoring features, such as:

Built-in overload safety shear pin: Shears off under excessive load to protect more expensive drive and structural components.

Integrated bearing monitoring sensor interface: Allows installation of temperature or vibration sensors for predictive maintenance.

4. Precise Positioning

Equipped with Demag Offset Gear Motor Drive: Demag's offset (or hollow shaft) gear motor is directly mounted on the wheel axle, offering a compact design and high transmission efficiency. Its precision gear system ensures minimal backlash, enabling accurate control during start-stop operations. This is critical for applications requiring repeated precise positioning (e.g., warehouse picking, precision assembly).

Fixed-point positioning: The entire system (including motor, brake, and wheel assembly) is optimized through integrated design, ensuring high rigidity. This prevents "creeping" or "shifting" caused by component deformation or backlash during start-stop cycles, achieving reliable fixed-point stopping.

5. Industrial DRS Wheel System Range:

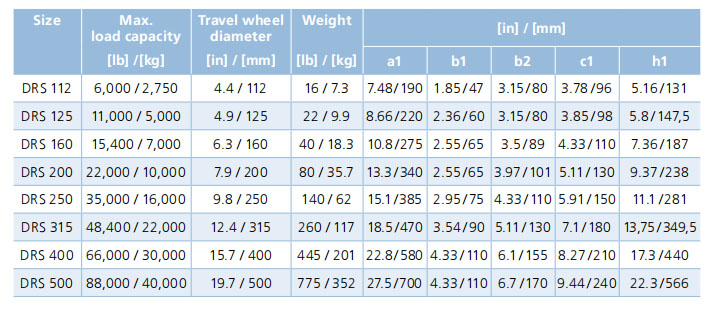

The different product families can be seamlessly integrated into the modular drive system: 8 sizes and (DRS 112mm、125mm、160mm、200mm、300mm、350mm、400mm、500mm)

In conclusion, translation wheel blocking systems are engineered for a wide range of applications where precise, reliable, and efficient movement is essential. These drive units are ideal for use in overhead cranes, hoists, and other material handling equipment, providing exceptional performance even in demanding environments. Whether you require a standard solution or a custom-built universal travel wheel systems tailored to your specific needs, MAILUN offers flexible options to meet diverse operational requirements. MAILUN manufacturer is dedicated to delivering high-quality, durable products that ensure smooth and reliable movement for your systems. For expert guidance and support in selecting the right drive wheel blocks for your application, please contact us at MAILUN.