Case

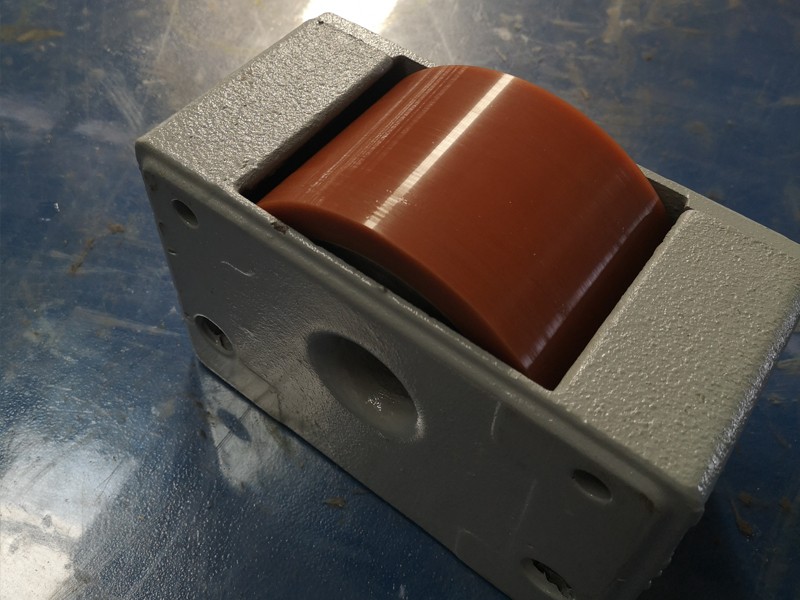

The Application of Demag Wheel Block on RGV

Demag wheel blocks are widely recognized for their high performance, reliability, and modular design. In the context of Rail Guided Vehicles (RGVs)—an essential component in automated material handling systems—Demag wheel blocks play a crucial role in ensuring smooth, safe, and efficient transportation across rails.

Demag wheel blocks are widely recognized for their high performance, reliability, and modular design. In the context of Rail Guided Vehicles (RGVs)—an essential component in automated material handling systems—Demag wheel blocks play a crucial role in ensuring smooth, safe, and efficient transportation across rails.

1. Function of Wheel Blocks in RGVs:

In RGV systems, wheel blocks are responsible for supporting the load of the vehicle, guiding it precisely along the track, and transmitting the drive force. The performance of the wheel block directly affects the overall stability, accuracy, and service life of the RGV.

2. Why Demag Wheel Blocks?

Demag wheel blocks offer several features that make them ideal for use on RGVs:

High Load Capacity: Supports heavy payloads while maintaining compact dimensions.

Precision Machining: Ensures accurate rail guidance and smooth motion.

Integrated Design: Allows for easy integration with drive systems and frameworks.

Modularity: Offers multiple mounting options and wheel configurations (e.g., solid, hollow shaft).

Durability: Designed for continuous operation in industrial environments with low maintenance requirements.

3. Application Benefits on RGVs:

a) Improved Operational Stability:

Demag wheel blocks provide excellent rolling performance, which contributes to vibration-free and stable motion of the RGV along its track, even under high-speed conditions.

b) Enhanced Positioning Accuracy:

The high manufacturing precision of the wheel blocks ensures that the RGV maintains alignment with its guide rails, enabling accurate stops and starts—crucial in automated loading/unloading processes.

c) Customizable Configurations:

Demag wheel blocks come in various sizes and configurations, such as single-flange, double-flange, or flangeless types. This allows for optimal customization to match the RGV’s track system and operational layout.

d) Ease of Maintenance and Replacement:

The modular and compact structure of Demag wheel blocks simplifies inspection, maintenance, and replacement, minimizing downtime in automated systems.

The use of Demag wheel blocks in Rail Guided Vehicles delivers unmatched reliability, precision, and adaptability in automated transport systems. Their integration helps RGVs achieve higher operational efficiency, reduced maintenance, and smoother logistics flow, making them a preferred choice in modern material handling applications.