Case

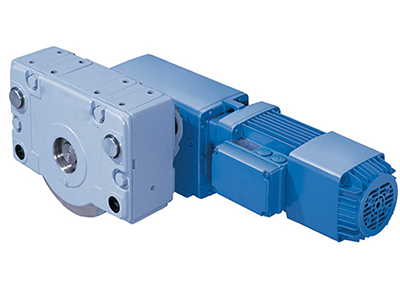

SEW Direct Integrated Motor on the Demag Wheel Design

The integration of an SEW direct drive motor into a Demag wheel system represents a high-performance solution for modern material handling and intralogistics applications. This combination delivers superior efficiency, compactness, and precise control, making it an ideal choice for Automated Guided Vehicles (AGVs), cranes, transfer carts, and other industrial transport systems.

The integration of an SEW direct drive motor into a Demag wheel system represents a high-performance solution for modern material handling and intralogistics applications. This combination delivers superior efficiency, compactness, and precise control, making it an ideal choice for Automated Guided Vehicles (AGVs), cranes, transfer carts, and other industrial transport systems.

1. Overview of SEW Direct Drive Motor

The SEW direct drive motor is a compact, gearless electric motor designed for maximum power density and energy efficiency. It eliminates the need for traditional gearboxes, reducing mechanical complexity and enhancing performance. Direct drive systems offer high torque at low speeds, making them suitable for applications where precision and smooth motion are critical.

Key Features:

High torque density

Low maintenance (gearless design)

Precise speed and position control

Compact and lightweight

2. Demag Wheel Design

Demag is a globally recognized manufacturer of wheel blocks and drive systems. The Demag wheel block system is known for its modular design, durability, and ability to handle high loads. It can be customized with various drive options, including integrated motors.

Wheel Features:

Robust construction for heavy-duty applications

Options for different wheel materials (e.g., steel, polyurethane)

Hollow shaft and solid shaft designs

Easy maintenance and long service life

3. Integration Benefits

By integrating the SEW direct drive motor directly into the Demag wheel housing, several operational and design advantages are achieved:

Space Efficiency: The compact integration eliminates the need for separate motor mounts or couplings, making it suitable for confined spaces.

High Efficiency: Direct power transmission from motor to wheel reduces energy losses compared to geared systems.

Reduced Maintenance: Fewer mechanical components mean lower wear and less frequent service requirements.

Improved Precision: The integrated system allows for accurate control of wheel movement, which is essential in automated systems.

Enhanced Safety: Integrated motors support advanced control features like torque limitation and smooth start/stop motion.

4. Customization and Flexibility

Both SEW and Demag offer modular solutions that can be tailored to specific application requirements. The integrated motor-wheeled system can be customized in terms of:

Wheel size and tread material

Motor power and control features (encoder, brake, etc.)

Mounting configurations

Load capacity

The SEW direct integrated motor on the Demag wheel design is a cutting-edge solution that enhances the performance, efficiency, and reliability of motion systems in industrial automation. Its seamless integration, low maintenance, and high precision make it a preferred choice for demanding applications in modern manufacturing and logistics.