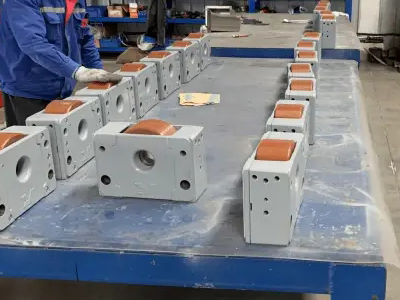

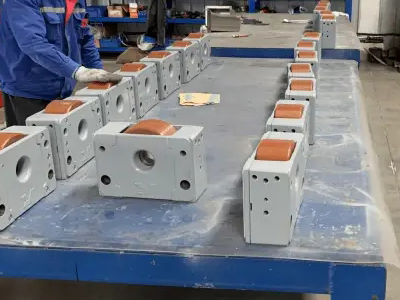

DRS Wheel Block System

High Load Capacity DRS Wheel Block in Automated Systems

Among the critical components enabling seamless material handling is the automatic handling drive travel wheel block—a robust solution designed to optimize the movement of goods in automated systems.

Among the critical components enabling seamless material handling is the automatic handling drive travel wheel block—a robust solution designed to optimize the movement of goods in automated systems. Whether deployed in warehouses, production lines, or heavy machinery, this component plays a pivotal role in ensuring smooth operations.

What Is a Travel Wheel Block?

A travel wheel block is a mechanized assembly that integrates wheels, motors, bearings, and control systems to facilitate the guided movement of automated equipment. In the context of automatic handling systems, it serves as the driving force for vehicles like automated guided vehicles (AGVs), conveyor systems, or robotic carriers. The "drive" aspect refers to its motorized capability, enabling autonomous navigation and load transportation with minimal human intervention.

Key Features of Modern Travel Wheel Block

High Load Capacity: Engineered to handle heavy-duty applications, advanced travel wheel blocks are built using high-grade steel or alloy materials. They support loads ranging from a few hundred kilograms to several tons, making them ideal for industries like automotive manufacturing, aerospace, and logistics.

Precision and durability: Equipped with sealed bearings and anti-wear components, these blocks withstand harsh environments, including exposure to dust, moisture, and temperature fluctuations. Corrosion-resistant coatings further extend their lifespan, reducing downtime for replacements.

Integrated automation: Modern wheel blocks feature built-in sensors and compatibility with Industry 4.0 protocols (e.g., IoT, CAN bus). This allows real-time monitoring of speed, torque, and alignment, enabling adaptive responses to operational changes.

Safety mechanisms: Safety is paramount in automated systems. Travel wheel blocks often include emergency braking systems, overload detection, and anti-collision sensors to prevent accidents and protect both machinery and personnel.

Low maintenance design: Modular construction simplifies maintenance. Components like motors or wheels can be replaced individually, minimizing service interruptions. Self-lubricating bearings also reduce the need for frequent manual upkeep.

Applications Across Industries

• Warehousing & Logistics: AGVs equipped with travel wheel blocks streamline inventory management, enabling 24/7 goods transportation in e-commerce fulfillment centers.

• Manufacturing: In assembly lines, these blocks ensure precise positioning of components, enhancing production accuracy.

• Heavy industries: Used in cranes or gantry systems, they support the movement of bulky materials in construction or shipbuilding.

By combining strength, intelligence, and resilience, it empowers businesses to achieve faster throughput, lower operational costs, and safer workflows.